Design Validation: Physical Prototype Se Pehle Virtual Testing Kyun Zaroori Hai?

Aksar inventors aur companies aik idea sochti hain aur foran uska physical prototype (model) banwa leti hain. Lekin jab woh model real-world mein fail hota hai, to unka hazaron dollars ka material aur hafton ka waqt zaya ho jata hai. Design Validation aur Virtual Prototyping woh process hai jo is nuqsan se aapko bachata hai.

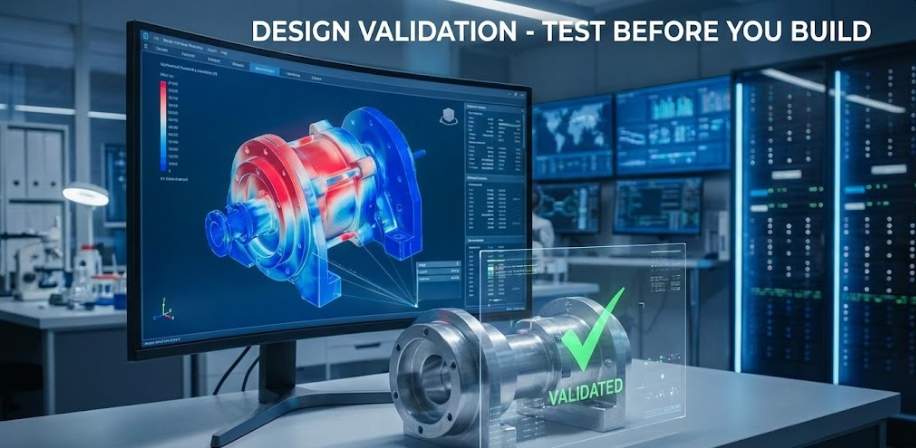

CADI Pro mein hum aapke product ko factory bhejne se pehle computer ki virtual environment mein test karte hain, taake aapko 100% yaqeen ho ke aapka design kaam karega.

1. Virtual Prototyping Kya Hai?

Virtual Prototyping ka matlab hai ke aapka 3D model sirf ek tasveer nahi hai, balkay woh software mein aik ‘zinda’ machine ki tarah behave karta hai. Hum us par hawa ka dabao, garmi, aur physical wazan (load) daal kar dekhte hain ke woh kahan se toot sakta hai ya kahan se bend ho sakta hai.

2. Design Validation Ke 3 Marahil

Stage A: Interference Aur Fitment Check

Hum check karte hain ke kya assembly ke saare parts aik doosre mein theek se fit ho rahe hain? Kya koi part kisi doosre part se takra (clash) to nahi raha? Yeh “Static Analysis” hota hai jo assembly ki ghaltiyon ko pakarta hai.

Stage B: Kinematic Analysis (Motion Study)

Agar aapke product mein moving parts hain (jaise gears ya hinges), to hum unki motion ko simulate karte hain. Hum dekhte hain ke kya movement smooth hai? Kya kahin friction zaroorat se zyada to nahi?

Stage C: Environmental Simulation

Is mein hum product ko uski asli environment mein rakhte hain. Maslan, agar woh drone hai to hawa mein kaisa perform karega, aur agar woh koi engine part hai to sakht garmi mein uski shape kitni badlegi?

3. Case Study: Industrial Valve Failure Prevention

Masla: Aik client ne high-pressure gas valve design kiya tha. Unhein darr tha ke high pressure par valve ka handle toot sakta hai.

CADI Pro Ka Hal: Humne valve ka virtual prototype banaya aur us par 500 bar pressure simulate kiya. Simulation ne dikhaya ke handle ke joint par stress limit se 20% zyada hai.

Nateeja: Humne physical prototype banne se pehle hi design mein tabdeeli kar di. Is se client ke taqreeban $2,500 bach gaye jo physical testing aur material par zaya hone thay.

Technical FAQs: Design Validation Ke Baray Mein

1. Virtual testing physical testing ki jagah le sakti hai?

Virtual testing 90-95% tak accurate hoti hai. Yeh physical prototypes ki tadaad ko kam kar deti hai (maslan 10 ki jagah sirf 1 final prototype), jis se cost aur waqt dono bachte hain.

2. Kya chote products ki validation bhi zaroori hai?

Bilkul. Ek chota plastic clip bhi agar mass production mein fail ho jaye, to hazaron units ka loss hota hai. Validation har scale par faida-mand hai.

3. Design Validation ke liye kaunse softwares istemal hote hain?

CADI Pro mein hum SolidWorks Simulation, ANSYS, aur SimScale jaise advanced tools istemal karte hain jo industry standard hain.

Apne design ko ‘Hit and Trial’ par mat chodein. Professional validation ke saath apne project ko kamyab banayein. Aaj hi CADI Pro ki expert team se rabta karein.

Thank you

The CadiPro Team