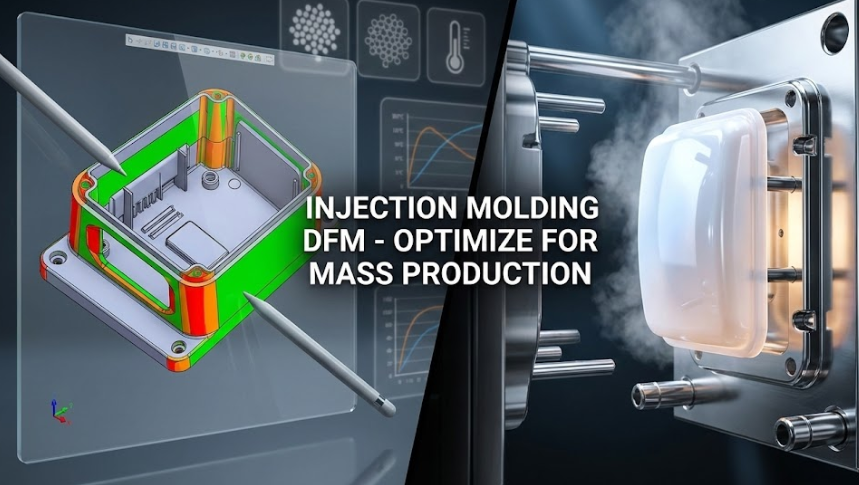

Injection Molding Design: Plastic Parts Ko Mass Production Ke Liye Kaise Optimize Karein?

Jab aap hazaron ya lakhon ki tadaad mein plastic parts banana chahte hain, to Injection Molding sab se behtareen tareeqa hai. Lekin, plastic design ke apne sakht usool hain. Agar aapka design “Mold-Friendly” nahi hai, to aapko Warpage (part ka mud jana), Sink Marks (satah par garhay), ya Flash jaise masail ka samna karna pad sakta hai.

CADI Pro mein hum aapke design ko DFM (Design for Manufacturing) ke usoolon par parakhte hain taake aapka product sasta, mazboot aur be-daag bane.

1. Plastic Design Ke 3 Sunehri Usool

Injekshan molding mein kamyabi ke liye in technical pehluon ka khayal rakhna lazmi hai:

- Uniform Wall Thickness: Agar part kahin se mota aur kahin se patla ho, to thanda hone par woh tedha ho jayega. Hum yaqeeni banate hain ke poore part mein thickness barabar rahe.

- Draft Angles: Mold se part ko aasani se nikalne ke liye deewaron ko thora sa tircha (angle) karna padta hai. Iske baghair part mold mein phans sakta hai ya us par scratches aa sakte hain.

- Ribs aur Bosses: Part ko mazboot banane ke liye hum motayi barhane ki bajaye “Ribs” ka istemal karte hain, jo kam material mein zyada strength dete hain.

2. Mold Flow Analysis: Virtual Testing

CADI Pro sirf design nahi karta, balkay hum Mold Flow Simulation bhi karte hain. Is se humein pehle hi pata chal jata hai ke:

- Pighla hua plastic mold mein kahan tak pohnchega?

- Kahin hawa (Air Traps) to phans nahi rahi?

- Cooling time kitna lagega?

3. Case Study: Consumer Electronics Enclosure

Masla: Aik client hamare paas ek handheld device ka design laye jismein cooling holes buhat complex thay. Unke pehle vendor ne kaha ke iska mold buhat mehnga banega kyunke ismein “Side Actions” (moving parts in mold) ki zaroorat thi.

CADI Pro Ka Hal: Humne holes ki orientation aur internal clips ko dobara design kiya. Humne design ko “Straight-Pull” mold ke mutabiq banaya, jismein kisi side action ki zaroorat nahi thi.

Nateeja: Mold banane ki cost $12,000 se kam ho kar $7,000 reh gayi. Client ne sirf design optimization se $5,000 bacha liye.

Technical FAQs: Injection Molding

1. Kya 3D printed part ko seedha mold kiya ja sakta hai?

Nahi. 3D printing mein draft angles aur wall thickness ka masla nahi hota, lekin molding mein yeh lazmi hain. Hum aapke 3D printed prototype ko “Molding-Ready” CAD mein convert karte hain.

2. Kaunsa plastic material behtar hai?

Yeh aapke product ke istemal par munhasir hai. ABS mazbooti ke liye, Polypropylene (PP) lachak ke liye, aur Polycarbonate (PC) transparency ke liye behtareen hai.

3. “Sink Marks” se kaise bacha jaye?

Sink marks tab aate hain jab deewar (wall) zaroorat se zyada moti ho. Hum wall thickness ko optimize karke aur ribs ka sahi istemal karke isey khatam karte hain.

Apne mass production ke khwab ko haqeeqat banayein. Professional DFM aur Injection Molding design ke liye CADI Pro ki expert team se rabta karein.

Thank you

The CadiPro Team