MEP Coordination Ki Zarurat Kyun Parti Hai?

Aik bari building ya industrial plant ki tameer mein sab se bara masla tab aata hai jab on-site pipes aur ducts aik doosre se takra jate hain. MEP Coordination (Mechanical, Electrical, and Plumbing) aik aisa process hai jo construction shuru hone se pehle hi in tamam services ko digitally align karta hai taake site par koi masla na ho.

MEP Coordination Ke 3 Aham Marahil

1. 3D Modeling Aur Spatial Coordination

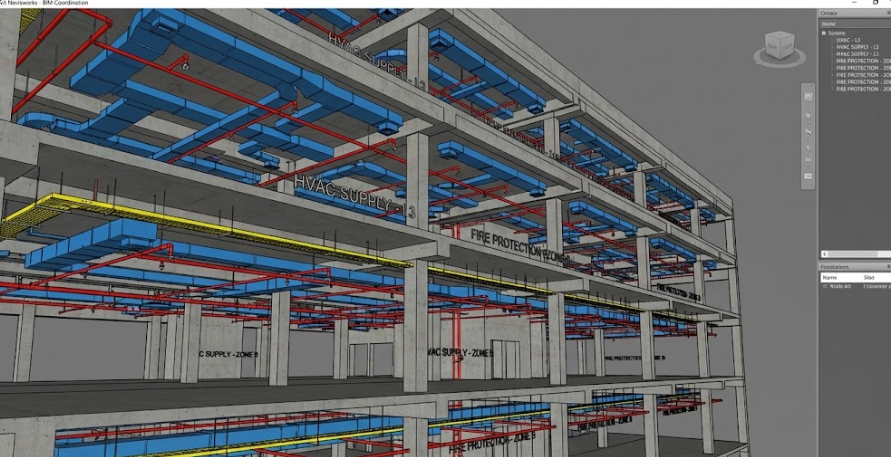

Hum Revit aur BIM tools ka istemal karte hue har system ka 3D model banate hain. Is se humein building ke andar mojood har inch ka pata chalta hai ke kahan pipe jayega aur kahan duct.

2. Automated Clash Detection

Navisworks jaise softwares ke zariye hum automated tests run karte hain jo batate hain ke kahan “Hard Clashes” (physical collision) ya “Soft Clashes” (clearance issues) mojood hain.

3. Detailed Shop Drawings

Jab coordination mukammal ho jati hai, toh hum ‘Shop Drawings’ nikalte hain. In drawings ko dekh kar site par mojood workers bina kisi ghalti ke installation kar sakte hain.

Client Ko Hone Wale Fawaid

- Zero Rework: Site par tod-phod ki zaroorat nahi parti, jis se waqt aur paisa dono bachte hain.

- Accurate BOQ: Aapko pehle se pata hota hai ke kitna material chahiye, jis se wastage nahi hoti.

- Maintenance Ease: Behtar coordinated systems ki maintenance asan aur sasti hoti hai.

Conclusion

CADI Pro mein hamari MEP team yaqeeni banati hai ke aapka architectural design aur technical services aik doosre ke saath mukammal ham-ahang hon. Hamari maharat aapke construction process ko smooth aur efficient banati hai.

Hamari makhsoos BIM services ke liye Services Page dekhein.

Thank you

The CadiPro Team