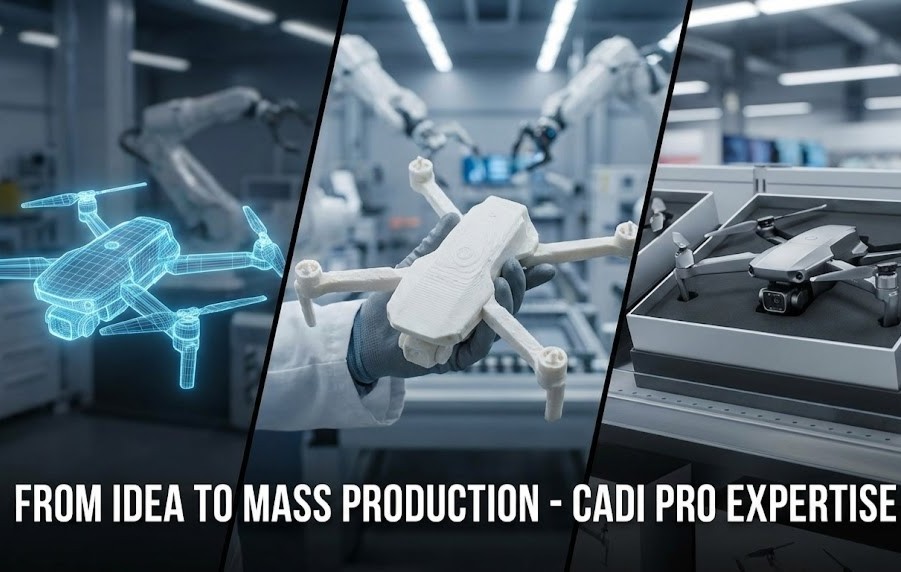

Prototype Se Mass Production: Apne Product Ko Market Tak Le Janay Ka Sahi Tareeqa

Ek naya idea hona ek baat hai, lekin us ideay ko ek aise product mein badalna jo hazaron ki tadaad mein factory se nikal sake, ek bilkul mukhtalif science hai. Aksar inventors aur startups pehla prototype to bana lete hain, lekin jab mass production ki baat aati hai, to unka design fail ho jata hai ya buhat mehnga padta hai.

CADI Pro mein hum aapke product ko “Production-Ready” banate hain. Is blog mein hum un marahil (stages) ka zikr karenge jo aapke khwab ko haqeeqat mein badalte hain.

1. Prototyping: Pehli Jhalak Aur Testing

Prototyping ka matlab hai apne design ka ek ‘working model’ banana. Yeh isliye zaroori hai taake aap dekh sakein ke kya product asal mein kaam kar raha hai ya nahi. Is stage par hum 3D Printing, CNC Machining, ya Vacuum Casting ka istemal karte hain.

CADI Pro Tip: Prototype sirf dikhne mein acha nahi hona chahiye, usay apne functional tests (load, heat, fitment) bhi paas karne chahiye.

2. DFM Optimization: Production Ke Liye Taiyari

Jab prototype paas ho jaye, to hum usay Design for Manufacturability (DFM) ke filters se guzarte hain. Is stage par hum dekhte hain ke:

- Kya part ki deewaren (walls) Injection Molding ke liye sahi hain?

- Kya hum material ki quantity kam kar ke cost bacha sakte hain?

- Kya assembly ka waqt kam kiya ja sakta hai?

3. Case Study: Startup Se Scalable Success Tak

Masla: Ek client hamare paas ek Smart Home device ka design lekar aaye jo unho ne 3D printing ke liye banaya tha. Jab unho ne 10,000 units ka rate liya, to manufacturing cost itni zyada thi ke product market mein bik nahi sakta tha.

CADI Pro Ka Hal: Humne unke design ko “Part Consolidation” ke zariye 12 parts se kam karke sirf 5 parts par laye. Humne material ko analyze kiya aur aisi shape banayi jo sasti Injection Molding ke liye perfect thi.

Nateeja: Manufacturing cost mein 40% kami aayi aur assembly ka waqt 15 minute se kam ho kar sirf 4 minute reh gaya. Aaj woh product kamyabi se hazaron ki tadaad mein ban raha hai.

4. Tooling Aur Final Production

Jab design finalize ho jata hai, to asli kaam shuru hota hai: Molds aur Dies banana. Yeh buhat mehnga marhala hota hai, isliye yahan ghalti ki gunjayish zero hoti hai. CADI Pro aapko sahi manufacturers dhoondne aur unhein technical support dene mein madad karta hai.

Technical FAQs: Log Kya Poochte Hain?

1. Prototype aur Production Model mein kya farq hota hai?

Prototype aksar 3D printing jaisi “Additive” techniques se banta hai taake jaldi check ho sake. Production model “Subtractive” ya “Molding” techniques ke liye optimize kiya jata hai taake har unit sasta aur majboot bane.

2. Mass production shuru karne se pehle kitne prototypes chahiye?

Aam taur par 2 se 3 stages zaroori hain: Pehla ‘Proof of Concept’ ke liye, doosra ‘Functional Testing’ ke liye, aur teesra ‘Final Aesthetic/Golden Sample’ ke liye.

3. Kya CADI Pro manufacturing mein bhi madad karta hai?

Ji haan, hum sirf design nahi dete balkay hum aapko manufacturing vendors ke saath connect karte hain aur unhein technical drawings (blueprints) samjhane mein madad karte hain.

Apne product ko andazon par mat chodein. Professional engineering support ke liye aaj hi CADI Pro se rabta karein.

Thank you

The CadiPro Team