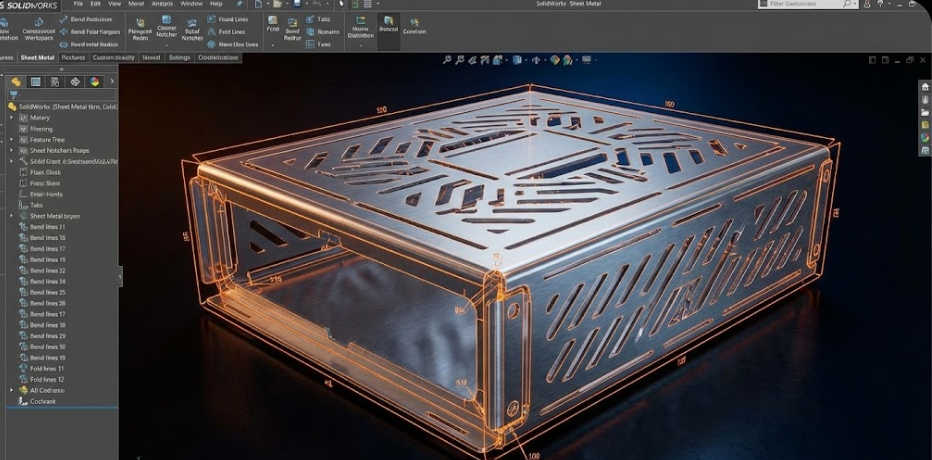

Sheet Metal Design Ka Industrial Kirdar

Modern manufacturing mein sheet metal aik nihayat aham aur versatile material hai. (2:31) Chahay woh computer enclosures hon ya industrial machinery ke frames, sheet metal design har jagah mojood hai. Lekin aik kamyab design wahi hai jo minimum material ke saath maximum strength faraham kare.

Sheet Metal Design Ke 5 Sunahri Usool

1. Bend Radius Ki Ahmiyat

Sheet metal ko bend karte waqt hamesha material ki thickness ke mutabiq inner bend radius ka intekhab karein. Agar radius boht kam hoga toh material mein cracks aa sakte hain, jo product ki life kam kar dete hain.

2. Bend Relief Aur Notching

Jahan bhi bend aur edge aik doosre ke kareeb hon, wahan ‘Bend Relief’ dena zaroori hai. Yeh material ko phatne se bachata hai aur design ko clean look deta hai.

3. Hole aur Slot ki Placement

Holes ko hamesha bend line se kam az kam 3x material thickness door rakhein. Agar holes bend ke boht kareeb honge toh bending ke waqt woh deform ho sakte hain.

4. Material Grain Direction

Steel aur Aluminum sheets mein grain direction hoti hai. Agar aap grain ke parallel bend karenge toh fracture ka khatra barh jata hai. Hamesha koshish karein ke bends grain direction ke perpendicular hon.

5. Standard Gauge Selection

Hamesha market mein mojood standard sheet gauges ka intekhab karein. Custom thickness select karne se material ki availability aur cost dono ka masla ho sakta hai.

Strength Barhane Ke Advanced Tareeqay

- Hems: Sharp edges ko khatam karne aur stiffness barhane ke liye hems ka istemal karein.

- Ribs and Gussets: Bari sheets mein lachak khatam karne ke liye ribs ya gussets design karein taake wazan barhaye baghair mazbooti milay.

Conclusion

CADI Pro mein hum SolidWorks Sheet Metal module ka istemal karte hain taake aapko accurate flat patterns aur precision designs mil sakain. Hamare designs laser cutting aur CNC folding ke liye mukammal taur par optimized hote hain.

Mazeed technical information ke liye hamara Blog Section check karein.

Thank you

The CadiPro Team